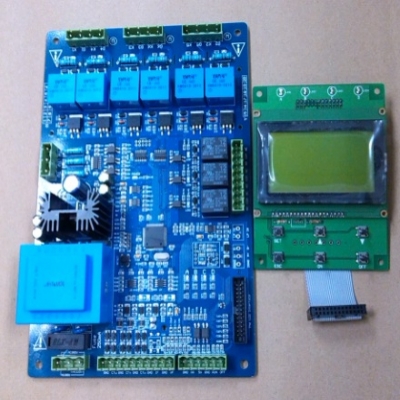

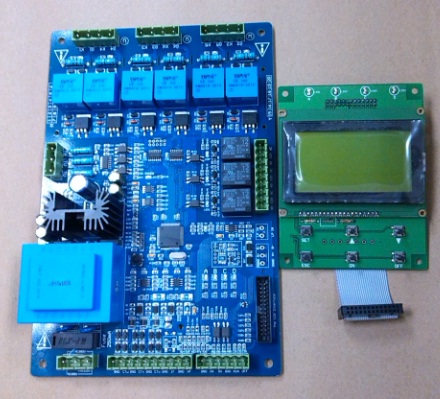

TC390 three-phase rectifier thyristor trigger board adopts 32-bit industrial-grade high-performance microprocessor, highly digital military quality design, supports network remote control and on-site control, Fuzzy-PID parameter open adjustment, integrated open-loop voltage regulation, closed-loop constant The three adjustment methods of voltage and constant current are integrated to control the thyristor to achieve constant voltage limit current or constant current limit voltage. The fault alarm and interface parameters are displayed in the Chinese menu on the LCD screen, and the set parameters are automatically stored. The control board has functions such as phase loss protection, power-on soft start, soft shutdown, constant current output, constant voltage output, overvoltage protection, overcurrent protection, and working status indication. With three-phase fully controlled bridge rectifier, double reverse star rectifier and thyristor anti-parallel AC trigger mode, it can trigger thyristor below 5000A, suitable for resistive loads, inductive loads, Various load types such as capacitive load and transformer primary side are widely used in electrolytic plating, charging and discharging, three-phase thyristor power supply, electric heating temperature control and other equipment.

The three-phase digital rectifier thyristor trigger board has a variety of given control signal options, supports 0-5Vdc, 0-10Vdc, 0-10mA, 4-20mA and other analog input automatic control modes, and can also be used with a potentiometer (10K 2W ) And manual control through the panel buttons, flexible and convenient, all parameters are digital, no temperature drift change, improve the adjustment accuracy and power utilization efficiency, reduce the pollution of the power supply, with high voltage regulation accuracy, reliability and stability. At the same time, the control board has strong anti-interference ability, adopts unique anti-interference measures, runs normally in harsh interference environment, and uses isolation technology for all outputs, has multiple protection functions, and has a wide range of applications.

1. Performance characteristics:

1.1. Using 32-bit industrial-grade high-speed microprocessor, LCD display with Chinese menu operation, fully automatic SMD process manufacturing, stable and reliable performance;

1.2. With digital constant current and voltage function and current and voltage limit function, it can accurately control the load and protect the abnormal over-current and over-voltage;

1.3. Perfect fault detection and alarm function, real-time detection of load status, load current, control signal, feedback signal loss and other parameters;

1.4. Intelligent PID control scheme, open parameters, can be flexibly set to any physical quantity, adapt to different types of loads, and have good dynamic characteristics.

1.5. Phase loss protection: When the main circuit power supply has a phase loss, it will alarm and prompt, and control the load to stop output in real time;

1.6. Interface compatibility: support 0-5Vdc, 0-10Vdc, 0-10mA, 4-20mA and other automatic input signals, directly interface with various instruments and PLC, and can be manually controlled by potentiometer;

1.7. Overload protection: Start to judge whether the load is overloaded after starting, and stop running when the protection time is set for continuous overload, and the alarm relay will output at the same time;

1.8. Soft start: When starting, the output voltage will gradually increase from zero to 100% to eliminate the impact on the grid and itself when the load is running. The soft start time parameter can be set;

1.9. Soft shutdown: When stopping, the output voltage will gradually decrease from 100% to zero to eliminate the impact on the grid and itself when the load stops. The soft shutdown time parameter can be set;

1.10. With the function of automatically identifying phase sequence, there is no phase sequence requirement for the power supply of the control panel, no external synchronization signal is required, debugging is not required, and the wiring is convenient;

1.11, the current loop (voltage loop) feedback input signal supports various analog input signals such as transformers, Hall current (voltage) sensors, 0-75mV shunts, and 0-5V;

1.12, can be remotely controlled by PLC or other equipment, MODBUS field bus communication function, RS485 fully isolated control (optional)

1.13. At the same time, it has the function of running time query, recording this running time and accumulated running time;

1.14. The control board is designed to prevent the thyristor trigger interface from burning out, and it supports input and output multi-function expansion boards.

1.15. The thyristor drive interface is equipped with double-row LED indicators. The green light indicates whether the trigger board is faulty, and the red light indicates whether the external control line is correct. You can quickly check the error location;

2. Technical specifications:

| 项目 | 参数 | 单位 | 说明 |

| 工作电源 | AC220V/380V ±15% 50/60HZ | Vac | 可根据客户要求订制 |

| 调压范围 | 0~100 | % | 直流电压 |

| 恒流范围 | 0~100 | % | 直流电流 |

| 调节输出分辨率 | 1/4000 |

|

|

| 移相范围 | 0~175° | 角度 |

|

| 触发容量 | <5000 | A(安培) |

|

| 绝缘体强度 | 3500VAC 1分钟 |

|

|

| 调节精度 | 优于1% |

|

|

| 三相触发不平衡度 | ≤0.3° |

|

|

| 报警继电器触点容量 | 250VAC/10A |

|

|

| 软启动时间 | 1~200 | S(秒钟) |

|

| 缓关闭时间 | 0~200 | S(秒钟) |

|

| 空载功耗 | <12VA | W(瓦特) |

|

| 显示方式 | LCD液晶屏 |

|

|

| 控制方式 | 面板输出操作、DC0-5V、DC0-10V、0-10mA、4-20mA、10K电位器 |

| 适用负载 | 适用于阻性负载、感性负载、变压器一次侧等 |

| 工作环境温度 | -20~50 | ℃(摄氏度) | 不结露 |

| 工作环境湿度 | ≤90% | %(相对温度) | 不结露 |

| 外形尺寸 | 240X160X50 | mm(毫米) |

|

| 安装方式 | 固定安装式 |

|

|

| 重量 | 1000 | g(克) | 不带附件的基本单元 |